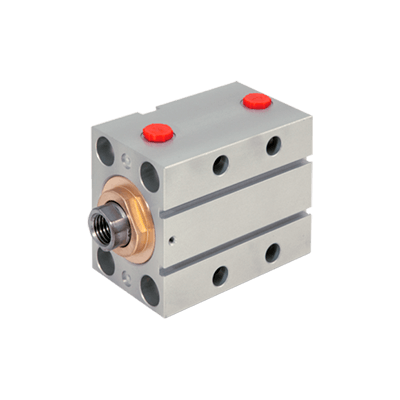

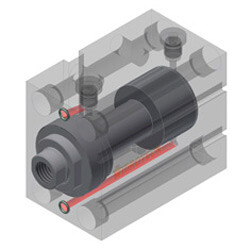

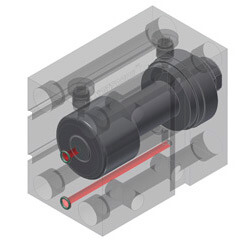

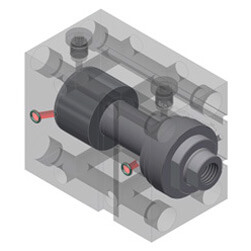

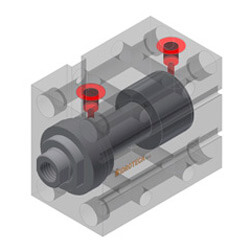

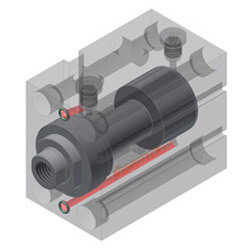

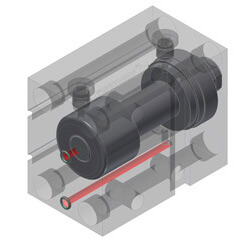

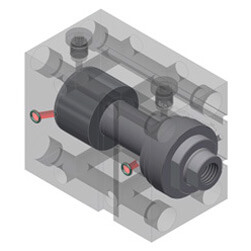

Short stroke hydraulic cylinders

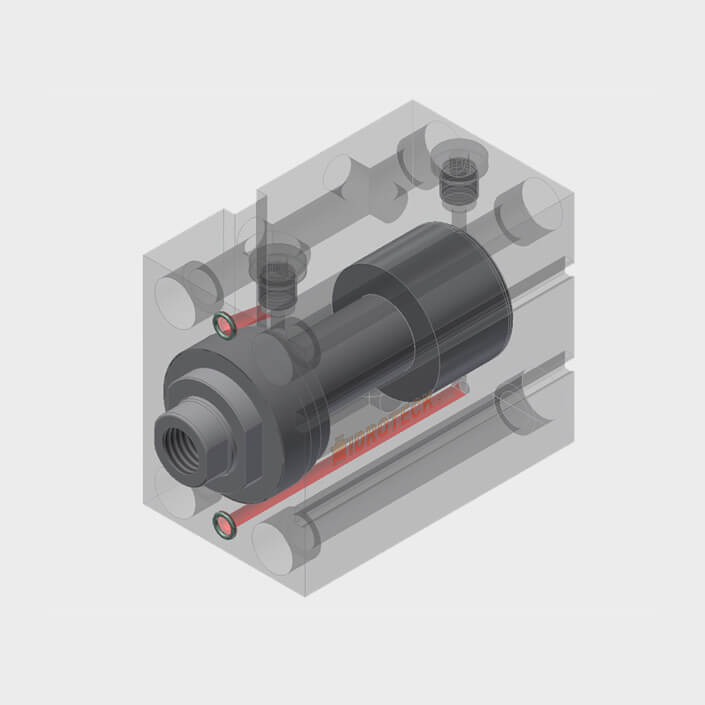

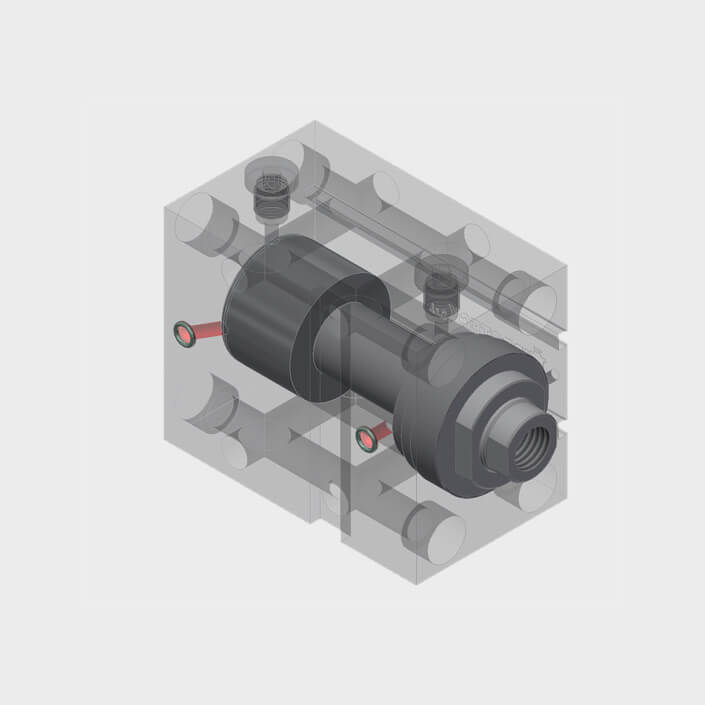

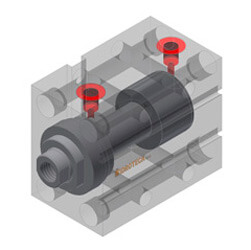

Idroteck short stroke hydraulic cylinders are made of aluminium or steel, to guarantee increased performance. Aluminium hydraulic cylinders can be used up to a pressure of 120 Bar. Steel hydraulic cylinders are used in heavy duty applications where maximum performance is required and can be used up to 250 Bar. The available series of short stroke cylinders are divided according to the type of power supply, with the choice of different types of fastening.

Having a dynamic and cutting-edge technical department, allows Idroteck to guarantee the production of custom hydraulic cylinders according to the requests of each individual customer.